-

The Ultimate Guide to Jacquard Knitting Machines: Boosting Efficiency and Creativity

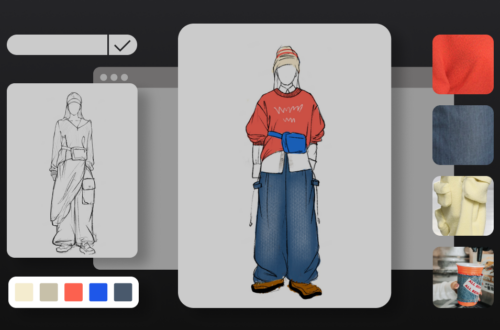

The Ultimate Guide to Jacquard Knitting Machines: Boosting Efficiency and Creativity Jacquard knitting machines have revolutionized the textile industry by enabling intricate pattern designs with unmatched precision. These advanced devices automate complex weaving processes, allowing manufacturers and hobbyists to produce detailed fabrics efficiently. Whether you’re in fashion, upholstery, or custom crafts, understanding these machines can elevate your projects. Key Features of Modern Jacquard Knitting Machines Modern Jacquard Knitting Machine models come equipped with digital controls, high-speed mechanisms, and compatibility with various yarn types. Key functionalities include programmable pattern libraries, automatic tension adjustment, and energy-efficient operations. These features reduce manual labor while enhancing output quality, making them ideal for bulk production…

-

The Ultimate Guide to Jacquard Knitting Machines: Revolutionizing Textile Production

The Ultimate Guide to Jacquard Knitting Machines: Revolutionizing Textile Production In the ever-evolving world of textile manufacturing, the Jacquard Knitting Machine stands as a pinnacle of innovation. This advanced equipment has transformed how intricate patterns and complex designs are woven into fabrics, enabling mass production of detailed textiles that were once only possible through meticulous hand-weaving. By utilizing a series of punched cards or digital controls, these machines offer unparalleled precision and efficiency. From fashion to home décor, the applications are vast. Designers and manufacturers leverage this technology to create unique, high-quality products that meet modern consumer demands for customization and variety. How Does a Jacquard Loom Work? The core…

-

The Ultimate Guide to Tissue Paper Making Machines: Efficiency, Technology, and Cost Analysis

**Understanding Tissue Paper Manufacturing Technology** The modern tissue paper making machine has revolutionized hygiene product manufacturing. These advanced systems integrate automation, precision engineering, and energy-saving mechanisms to deliver superior tissue quality while minimizing operational costs. Whether producing facial tissues, toilet paper, or napkins, manufacturers rely on these machines to maintain competitive efficiency. **Key Efficiency Metrics in Tissue Production** Efficiency remains paramount in tissue manufacturing. High-speed machines can produce up to 2,000 meters per minute while maintaining consistent sheet quality. Factors like fiber utilization rates, water consumption, and energy efficiency directly impact profitability. Modern systems feature heat recovery mechanisms and optimized press sections that reduce energy consumption by up to 30%…

-

The Ultimate Guide to Tissue Paper Making Machines: Efficiency, Types, and Innovations

The Ultimate Guide to Tissue Paper Making Machines: Efficiency, Types, and Innovations The tissue paper industry relies on advanced machinery to meet global demand for hygiene and paper products. Whether you’re a manufacturer or investor, understanding tissue paper making machines is essential for optimizing production and staying competitive. Key Components and Workflow A modern tissue paper making machine integrates several stages: pulping, forming, pressing, drying, and winding. High-efficiency systems reduce energy consumption while maintaining output quality, making them ideal for large-scale operations. Types of Tissue Paper Machines From crescent former to suction breast roll machines, each type offers unique benefits. Automated models enhance speed and precision, catering to diverse product…

-

The Ultimate Guide to Paper Cup Production Line: Efficiency and Innovation

The Ultimate Guide to Paper Cup Production Line: Efficiency and Innovation In today’s eco-conscious market, the demand for sustainable packaging solutions is skyrocketing. Paper cups have emerged as a popular alternative to plastic, driving the need for advanced paper cup production lines. These automated systems combine precision engineering with innovative technology to manufacture high-quality, biodegradable cups efficiently. Whether you’re a startup or an established manufacturer, understanding the intricacies of a Paper Cup Production Line can revolutionize your operations and boost profitability. Key Components of a Modern Paper Cup Production Line A fully integrated paper cup production line comprises several critical modules working in harmony. It begins with the unwinding unit,…

-

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability In today’s eco-conscious market, paper cups have become essential for beverage services worldwide. A modern Paper Cup Production Line integrates cutting-edge automation, sustainable material handling, and precision engineering to meet global demand efficiently. This guide explores how these systems balance productivity with environmental responsibility. Automated Workflow and Components Advanced paper cup machines feature multi-stage processes: printing, die-cutting, side seam heating, bottom sealing, and rim curling. High-speed servo motors and PLC controls ensure consistent output while minimizing material waste. Innovations like infrared drying and ultrasonic sealing enhance operational speed and cup durability. Eco-Friendly Material Integration Sustainability drives technological upgrades.…

-

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability In today’s eco-conscious market, the demand for sustainable packaging solutions is skyrocketing. A modern Paper Cup Production Line integrates cutting-edge automation, energy-saving mechanisms, and material optimization to meet global standards. This guide explores how these systems enhance productivity while minimizing environmental impact. Automated Forming and Sealing Advanced paper cup machines utilize precision molding and heat sealing to ensure leak-proof, durable cups. High-speed servo motors and PLC controls enable consistent output, reducing manual intervention and errors. Resource Efficiency and Waste Reduction Innovative lines incorporate recycled paperboard and water-based coatings. Automated trimming and recycling subsystems repurpose excess material, slashing waste…

-

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability In today’s eco-conscious market, the demand for sustainable packaging solutions is skyrocketing. Paper cups have become a staple in the food and beverage industry, and understanding the intricacies of a Paper Cup Production Line is crucial for businesses aiming to enhance efficiency and reduce environmental impact. This comprehensive guide explores how modern technology transforms raw materials into high-quality paper cups efficiently. Automated Paper Cup Forming Modern production lines utilize advanced automation to shape paper blanks into cups seamlessly. Precision engineering ensures consistent cup dimensions, reducing material waste and boosting output rates. Automated systems also allow for quick changeovers…

-

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability

The Ultimate Guide to Paper Cup Production Line: Efficiency, Technology, and Sustainability In today’s eco-conscious world, the paper cup production line has become a cornerstone of sustainable packaging. This guide dives into how modern lines boost efficiency, leverage cutting-edge technology, and support environmental goals. Whether you’re a manufacturer or a business owner, understanding these aspects can transform your operations. Efficiency in Paper Cup Manufacturing Efficiency is key to reducing costs and meeting high demand. Automated Paper Cup Production Line systems streamline processes from paper feeding to cup forming, minimizing waste and labor. Advanced sensors and IoT integration enable real-time monitoring, ensuring consistent output and quick adjustments. Automation and Workflow Optimization…

-

Top 5 Cement Brick Machine Models for Efficient Construction in 2024

Top 5 Cement Brick Machine Models for Efficient Construction in 2024 In the rapidly evolving construction industry, choosing the right equipment is crucial for efficiency and cost-effectiveness. Cement brick machine models have advanced significantly, offering enhanced automation and durability. This article highlights the top five models that stand out in 2024 for their performance and innovation. Automated Block Production Systems Modern cement brick machines integrate smart technology to streamline operations. These systems feature programmable logic controllers (PLCs) for precise brick molding, reducing manual labor by up to 70%. Key benefits include faster production cycles and consistent output quality, making them ideal for large-scale projects. Eco-Friendly Brick Manufacturing Sustainability is a…