-

The Ultimate Guide to Circular Knitting Machines: Types, Uses, and Modern Innovations

The Ultimate Guide to Circular Knitting Machines: Types, Uses, and Modern Innovations The world of textile manufacturing is driven by incredible machinery, and at the heart of fabric production for apparel, home goods, and technical textiles lies the circular knitting machine. Unlike flat knitting, these machines create a continuous tube of fabric, offering unparalleled speed and efficiency. This ultimate guide will explore the different types, their vast applications, and the cutting-edge innovations shaping the industry today. Understanding the Core Types of Circular Knitting Machines Not all circular knitting machines are the same. They are primarily categorized by their needle bed type and the fabric they produce. Single Jersey Machines: The…

-

The Ultimate Guide to Taishong Oiling Machines: Efficiency & Innovation

# The Ultimate Guide to Taishong Oiling Machines: Efficiency & Innovation In the world of industrial lubrication, precision, reliability, and innovation are paramount. This is where **Taishong oiling machines** stand out, offering cutting-edge solutions designed to maximize efficiency and minimize downtime across various manufacturing and processing sectors. ## **Detailed Functionality and Core Advantages** Taishong’s engineering philosophy centers on creating systems that deliver consistent, precise lubrication. These machines are built to handle diverse viscosities and application points, ensuring every component receives the exact amount of oil required for optimal performance and longevity. ### **Precision Automation for Peak Performance** The hallmark of a Taishong system is its automated precision. By eliminating manual,…

-

Top 5 Knitting Machine Belts: A Guide to Selection, Maintenance & Replacement

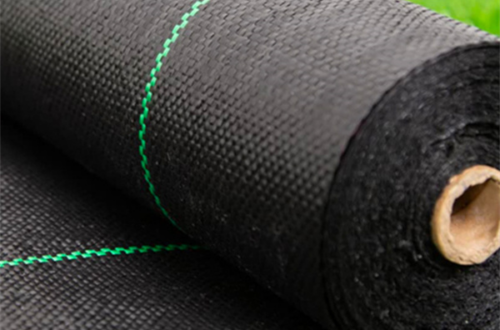

Top 5 Knitting Machine Belts: A Guide to Selection, Maintenance & Replacement For any knitting operation, efficiency is paramount. A critical yet often overlooked component in achieving this is the humble knitting machine belt. These belts are the workhorses that drive the precise, synchronized movements of your machine. Choosing the wrong one can lead to downtime, poor fabric quality, and increased costs. This guide will walk you through the top 5 belt types, how to select the right one, and best practices for care. Detailed Function and Selection Guide Not all belts are created equal. The ideal knitting machine belt must offer minimal stretch, high tensile strength, and excellent flexibility…

-

The Ultimate Guide to Electrical Cleaning Equipment: Types, Uses, and Best Practices

# The Ultimate Guide to Electrical Cleaning Equipment: Types, Uses, and Best Practices Keeping your electrical systems and components clean is not just about aesthetics—it’s a critical aspect of safety, efficiency, and longevity. This guide dives into the world of **electrical cleaning equipment**, exploring the tools and solutions that professionals rely on to maintain peak performance and prevent costly failures. ## **Detailed Functional Introduction** Electrical cleaning encompasses a range of specialized products designed to remove contaminants like dust, grease, oil, and carbon deposits without damaging sensitive components. The primary categories include: * **Contact Cleaners:** Fast-drying sprays that remove impurities from electrical contacts, switches, and relays to restore conductivity. * **Degreasers:**…

-

The Ultimate Guide to Choosing the Right Electrical Cleaning Equipment

The Ultimate Guide to Choosing the Right Electrical Cleaning Equipment Maintaining electrical systems is non-negotiable for safety and performance. The right electrical cleaning equipment is the cornerstone of this maintenance, preventing failures and extending equipment life. This guide will help you navigate the selection process. Understanding Electrical Cleaning Needs Before purchasing, assess your specific environment. Is it industrial machinery, data center servers, or automotive components? Different equipment demands different solutions, from precision aerosols to heavy-duty cleaners. Key Features and Solvent Types High-quality cleaners offer fast evaporation, non-flammability, and leave no residue. Dielectric strength is crucial for live or sensitive equipment cleaning. Choose between aerosol sprays for targeted application or bulk…

-

The Ultimate Guide to Choosing the Right Electrical Cleaning Equipment

The Ultimate Guide to Choosing the Right Electrical Cleaning Equipment Maintaining a safe and efficient electrical system is non-negotiable. Dust, grease, and other contaminants can lead to overheating, short circuits, and costly downtime. That’s where specialized electrical cleaning equipment comes in. This guide will help you navigate the options and select the perfect tools for your needs. Key Factors in Selecting Your Cleaning Tools Choosing the right equipment isn’t one-size-fits-all. Consider these critical factors: Application & Environment: Are you cleaning delicate circuit boards, large industrial panels, or high-voltage components? The setting (e.g., dusty factory, data center) dictates the required safety and precision level. Safety Certifications: Always prioritize tools rated for…

-

Top 10 Essential Electrical Cleaning Equipment for a Spotless and Safe Workspace

Top 10 Essential Electrical Cleaning Equipment for a Spotless and Safe Workspace Maintaining a clean electrical environment is non-negotiable for safety, efficiency, and equipment longevity. Using the right electrical cleaning equipment prevents malfunctions, reduces fire risks, and ensures optimal performance. This guide explores the top 10 tools and solutions every professional needs. Critical Tools for Electrical Maintenance From industrial facilities to data centers, specialized cleaning is paramount. Standard cleaners can leave conductive residues or cause damage, making purpose-built solutions essential. Non-Conductive Vacuum Systems These vacuums are specifically designed with grounded tools and HEPA filtration to safely remove dust and particulate from control panels, switchgear, and sensitive electronics without risking static…

-

The Ultimate Guide to Choosing the Right Electrical Cleaning Equipment

The Ultimate Guide to Choosing the Right Electrical Cleaning Equipment Maintaining a clean and safe electrical system is non-negotiable for optimal performance and longevity. Whether you’re a facility manager, a maintenance technician, or a DIY enthusiast, selecting the correct electrical cleaning equipment is crucial. This guide will help you navigate the options and make an informed decision. Key Factors in Selecting Electrical Cleaning Equipment Choosing the right tool isn’t just about picking a spray can. Consider these critical factors: Dielectric Strength and Safety Safety is paramount. Ensure any cleaner you use has a high dielectric strength, meaning it won’t conduct electricity and can be safely applied to energized components when…

-

The Ultimate Guide to Insulator Cleaning: Best Practices for Safety and Efficiency

The Ultimate Guide to Insulator Cleaning: Best Practices for Safety and Efficiency Maintaining a reliable and safe electrical grid is paramount. Contaminated insulators pose a significant risk, leading to flashovers, power outages, and safety hazards. This guide outlines the best practices for effective insulator cleaning to ensure operational safety and efficiency. Why Regular Insulator Maintenance is Critical Insulators prevent the unwanted flow of current to the earth. When dirt, salt, or industrial pollutants accumulate, they create a conductive layer. This contamination can cause “flashover,” a disruptive and dangerous electrical discharge across the insulator surface. Regular cleaning prevents this, ensuring system reliability and preventing costly downtime. Common Contaminants and Their Impact…

-

The Ultimate Guide to Effective Insulator Cleaning: Best Practices for Safety and Performance

The Ultimate Guide to Effective Insulator Cleaning: Best Practices for Safety and Performance Maintaining a reliable and efficient power grid is non-negotiable. A critical, yet often overlooked, component of this system is the humble insulator. Contaminated insulators can lead to flashovers, power outages, and significant safety hazards. This guide provides a comprehensive look at effective insulator cleaning methodologies to ensure optimal safety and performance of your electrical assets. Why Regular Insulator Maintenance is Crucial Insulators are designed to prevent the unwanted flow of electricity to the ground. However, pollutants like salt, dust, industrial emissions, and bird droppings can accumulate on their surface. This contamination creates a conductive layer, especially in…