-

The Ultimate Guide to Effective Insulator Cleaning: Best Practices for Safety and Performance

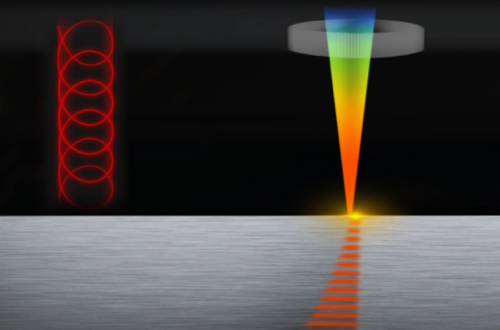

The Ultimate Guide to Effective Insulator Cleaning: Best Practices for Safety and Performance Maintaining a reliable and efficient power grid is non-negotiable. A critical, yet often overlooked, component of this system is the humble insulator. Contaminated insulators can lead to flashovers, power outages, and significant safety hazards. This guide provides a comprehensive look at effective insulator cleaning methodologies to ensure optimal safety and performance of your electrical assets. Why Regular Insulator Maintenance is Crucial Insulators are designed to prevent the unwanted flow of electricity to the ground. However, pollutants like salt, dust, industrial emissions, and bird droppings can accumulate on their surface. This contamination creates a conductive layer, especially in…

-

The Ultimate Guide to GRL Busbar: Design, Applications, and Benefits

The Ultimate Guide to GRL Busbar: Design, Applications, and Benefits In the world of modern power distribution, efficiency, reliability, and safety are paramount. Enter the GRL busbar, a sophisticated solution revolutionizing how we manage electrical currents in various industries. This guide delves deep into its design, diverse applications, and the compelling benefits it offers. Understanding GRL Busbar Design and Architecture The core of a GRL busbar system lies in its intelligent design. Unlike traditional cabling, it consists of sturdy metal strips or bars, typically made from copper or aluminum, housed within a protective enclosure. This design minimizes electrical resistance and maximizes current carrying capacity. Key Components and Material Selection High-conductivity…

-

What Is a GRL Busbar? A Comprehensive Guide to Design and Applications

What Is a GRL Busbar? A Comprehensive Guide to Design and Applications In the world of electrical power distribution, efficiency, reliability, and safety are paramount. Enter the busbar—a critical component that often operates behind the scenes. But what exactly is a GRL busbar, and why is it so important for modern electrical systems? This guide dives deep into its design, functionality, and wide-ranging applications. Understanding the GRL Busbar System A grl busbar refers to a busbar system associated with the GRL Group, a leader in electrical connectivity solutions. Fundamentally, a busbar is a metallic strip or bar, typically made of copper or aluminum, that conducts electricity within a switchboard, distribution…

-

The Ultimate Guide to Self-Fusing Silicone Rubber Tape: Uses, Benefits, and How-To

The Ultimate Guide to Self-Fusing Silicone Rubber Tape: Uses, Benefits, and How-To In the world of repairs, insulation, and protection, a unique material stands out for its versatility and ease of use: self-fusing silicone rubber tape. Unlike traditional adhesive tapes, it bonds only to itself, creating a seamless, waterproof, and durable layer. This guide explores everything you need to know. What is Self-Fusing Silicone Tape and How Does It Work? This specialized tape is made from high-quality silicone rubber. Its magic lies in the self-amalgamating process. When stretched and wrapped over itself, the layers fuse into a solid, rubbery mass without glue. It forms a permanent, airtight, and watertight seal…

-

What Is a GRL Busbar? A Comprehensive Guide

# What Is a GRL Busbar? A Comprehensive Guide In the world of electrical power distribution, efficiency, reliability, and safety are paramount. This is where the **GRL busbar** comes into play. But what exactly is it? Simply put, a busbar is a metallic strip or bar that conducts electricity within a switchboard, distribution board, or other electrical apparatus. The term “GRL” typically refers to a specific manufacturer or a proprietary system known for high-quality, innovative busbar solutions designed for optimal performance in demanding applications. ## **Detailed Functional Introduction** A GRL busbar system is far more than just a piece of metal. It is an engineered component critical for modern power…

-

What is a GRL Busbar? A Comprehensive Guide

What is a GRL Busbar? A Comprehensive Guide In the world of electrical power distribution, efficiency, safety, and reliability are paramount. This is where the GRL busbar comes into play. But what exactly is it, and why is it a critical component in modern electrical systems? Understanding the GRL Busbar System A GRL busbar is a specialized type of electrical conductor that provides a robust and low-impedance path for distributing power within an enclosure, such as a switchboard, panelboard, or data center power distribution unit (PDU). Unlike traditional cabling, a busbar is typically a solid metal bar—often made of copper or aluminum—designed to handle high current loads with minimal energy…

-

Unlock the Ultimate Taste: Exploring the Extra Flavor of Luosifen

Unlock the Ultimate Taste: Exploring the Extra Flavor of Luosifen For adventurous food lovers, the pungent aroma and complex taste of Luosifen, the iconic river snail rice noodle soup from Liuzhou, is a culinary badge of honor. But what if you could take this legendary dish to the next level? Enter the world of Luosifen extra flavor—a deeper, richer, and more intense experience that promises to unlock the true soul of this Chinese classic. What Makes “Extra Flavor” So Special? Standard instant Luosifen packs are already flavor bombs, but the “extra flavor” variants are engineered for the true connoisseur. This isn’t just about adding more spice; it’s about amplifying the…

-

The Ultimate Guide to Self-Fusing Silicone Rubber Tape: Uses, Benefits, and How-To

# The Ultimate Guide to Self-Fusing Silicone Rubber Tape: Uses, Benefits, and How-To **Self-fusing silicone rubber tape** is a remarkable and versatile tool found in countless toolboxes, from industrial maintenance to DIY home repairs. Unlike traditional adhesive tapes, it fuses to itself to form a permanent, waterproof, and flexible seal. This guide explores everything you need to know about this indispensable material. ## **Detailed Functional Overview** This unique tape is made from silicone rubber and contains no adhesive. When stretched and wrapped, its layers chemically bond to each other, creating a seamless, rubber-like sleeve. This fusion process makes it ideal for creating durable, airtight, and watertight seals on irregular shapes.…

-

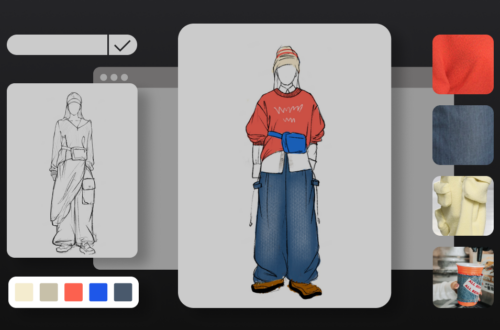

Illuminate Your Style: The Ultimate Guide to Luminous Clothing

Illuminate Your Style: The Ultimate Guide to Luminous Clothing Step out of the shadows and into the spotlight with luminous clothing. This isn’t just fashion; it’s a wearable light show that transforms you into the center of attention. Whether you’re a festival-goer, a night runner, or simply someone who loves to stand out, glowing apparel offers a unique blend of safety, style, and self-expression. This guide will illuminate everything you need to know. How Does Glow-in-the-Dark Apparel Work? Modern luminous clothing utilizes advanced technologies to create its radiant effect. The two primary methods are: Phosphorescent Materials: These fabrics are treated with special pigments that absorb and store light energy (from…

-

Illuminate Your Style: The Ultimate Guide to Luminous Clothing

Illuminate Your Style: The Ultimate Guide to Luminous Clothing Step into the spotlight and redefine your wardrobe with the future of fashion. Luminous clothing is no longer just a futuristic concept; it’s a vibrant, wearable technology that allows you to express your personality in a brilliantly new way. This guide will explore everything you need to know about these glowing garments. What is Luminous Apparel and How Does It Work? At its core, luminous apparel integrates light-emitting elements into fabric. This is typically achieved using flexible LED strips, electroluminescent (EL) wire, or advanced photoluminescent materials that store and emit light. These components are powered by small, rechargeable battery packs, often…