WHAT IS A LASER WELDING MACHINE? AN ARTICLE TO HELP YOU GET STARTED QUICKLY

What is a Laser Welding Machine? An Article to Help You Get Started Quickly

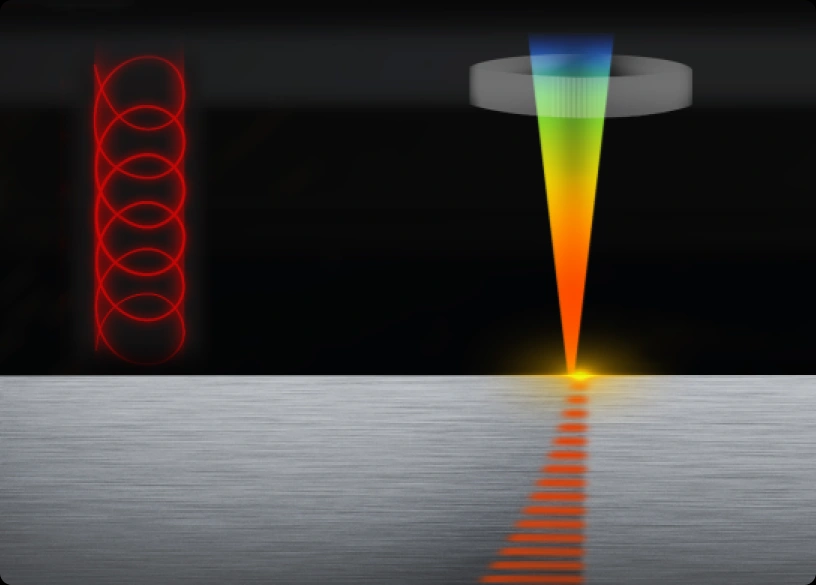

A laser welding machine is a powerful tool that uses a focused laser beam to melt and fuse materials, typically metals, with high precision. Unlike traditional welding methods, which involve applying heat through electrodes or flames, a laser welding machine uses a concentrated light source to achieve exact and controlled results. The advantages of this technology include greater precision, reduced heataffected zones, and a clean, smooth finish, making it ideal for industries that require highquality welds.

How Does a Laser Welding Machine Work?

At the core of a laser welding machine is a laser source, often a fiber or CO2 laser, which generates a concentrated beam of light. This beam is directed onto the material being welded. When the laser light hits the surface, it heats the material to its melting point, allowing it to flow and bond with other parts. The beam can be precisely controlled, which is especially important for welding thin or complex parts that require accuracy.

For materials that are difficult to weld, such as those with varying thickness or intricate designs, a 1000w handheld fiber laser welding machine offers flexibility and ease of use. It allows operators to move the laser beam to the exact location of the weld, which is perfect for jobs requiring high precision in tight spaces or irregular shapes.

Key Features of Laser Welding Machines

Laser welding machines have several features that make them stand out compared to traditional welding equipment. Here are some key advantages:

1. High Precision: Laser welding can produce intricate and precise welds, which is crucial in industries like electronics, medical devices, and aerospace.

2. Minimal HeatAffected Zone: The focused laser beam minimizes the area of material that is affected by heat, reducing the risk of warping and distortion.

3. Speed and Efficiency: Laser welding is faster than traditional methods, which increases production speed and reduces labor costs.

4. Clean Welds: The precision of laser welding leads to cleaner joints with minimal need for postweld cleaning or finishing.

These features make laser welding machines a preferred choice for applications requiring highquality welds with minimal finishing.

Applications of Laser Welding Machines

Laser welding machines are used in various industries, where precision and highquality results are a priority. Below are some common application fields:

1. Automotive Industry

In the automotive sector, laser welding machines are widely used to join parts such as car body panels, exhaust systems, and chassis components. The ability to weld thin metal sheets with precision is essential for maintaining the structural integrity and aesthetics of vehicle components.

2. Electronics Manufacturing

Laser welding is used to assemble delicate electronic components, such as batteries, circuit boards, and connectors. The precision of the laser beam ensures that small parts are welded together without damaging surrounding components.

3. Aerospace Industry

The aerospace sector requires extremely strong and precise welds, often for components that undergo high stress and extreme temperatures. Laser welding meets these demands by producing clean, strong welds without the distortion typically seen in traditional welding methods.

4. Jewelry and Watchmaking

Laser welding is perfect for working with precious metals in jewelry and watchmaking. The ability to perform delicate welding tasks on small, intricate parts without damaging the surrounding material makes it ideal for these industries.

5. Medical Devices

Laser welding is used in medical device manufacturing to join small, precise components, such as surgical instruments and implants. The sterile, highquality welds are critical in ensuring the safety and functionality of medical equipment.

Choosing the Right Laser Welding Machine

When purchasing a laser welding machine, several factors should be considered to ensure that the equipment meets your specific needs. These include:

1. Power Output:

Laser welding machines come in various power configurations, such as 1000w, 1500w, or higher. For many applications, a 1000w laser welding machine for sale is ideal as it provides a good balance of power and costeffectiveness for mediumduty welding tasks. However, higherpowered machines may be necessary for thicker materials or more intensive industrial applications.

2. Portability:

If you need a machine for welding in different locations or for small repairs, a 1000w handheld fiber laser welding machine could be the perfect solution. Its portability and ease of use make it a versatile tool for many industries.

3. Material Compatibility:

Ensure that the machine is suitable for the materials you plan to weld. Some machines work better on metals like steel, aluminum, or copper, while others may be designed for specific applications like plastics or ceramics.

4. Automation and Software:

Consider whether the laser welding machine offers advanced features such as automated scanning or programmable settings, which can improve efficiency and precision.

Benefits of Buying a Laser Welding Machine

Investing in a laser welding machine provides numerous benefits for businesses, including:

1. Higher Productivity:

Laser welding reduces the need for rework and minimizes downtime, increasing overall productivity.

2. Enhanced Quality:

The precision and cleanliness of laser welds result in fewer defects and higherquality products.

3. Cost Savings:

Although the initial cost of a laser welding machine may be higher than traditional welding equipment, the longterm savings in time, labor, and material costs often outweigh the investment.

Conclusion

A laser welding machine is a versatile and efficient tool that can help businesses achieve highquality, precise welds with minimal effort. Whether you’re considering a 1000w handheld fiber laser welding machine for portability or a 1000w laser welding machine for sale for mediumduty applications, the right machine can enhance your production capabilities and reduce the need for manual labor. Understanding the machine’s features, applications, and benefits is essential for making an informed decision, ensuring that you select the best equipment for your specific needs.