-

The Ultimate Guide to Gas Steam Boilers: Efficiency, Types & Selection

The Ultimate Guide to Gas Steam Boilers: Efficiency, Types & Selection Gas steam boilers are the powerhouse behind countless industrial processes, commercial heating systems, and even large-scale residential applications. Choosing the right one is critical for operational efficiency, cost savings, and meeting your specific steam requirements. This comprehensive guide breaks down everything you need to know. Understanding Gas Steam Boiler Efficiency Maximizing efficiency is the primary goal for any boiler operator. High-efficiency models convert more of the fuel’s energy into usable steam, directly reducing fuel costs and environmental impact. Key factors include thermal efficiency, which measures heat transfer effectiveness, and combustion efficiency, which focuses on complete fuel burning. Modern condensing…

-

The Ultimate Guide to Gas Fired Steam Boilers: Efficiency, Types & Selection

The Ultimate Guide to Gas Fired Steam Boilers: Efficiency, Types & Selection In the world of industrial and commercial heating, gas fired steam boilers remain a cornerstone technology. They are prized for their reliability, powerful output, and ability to meet demanding process and space heating needs. This comprehensive guide will delve into everything you need to know, from how they work to selecting the perfect model for your application. How Does a Gas Fired Steam Boiler Work? At its core, a gas fired steam boiler is a closed vessel where water is heated by the combustion of natural gas or propane. The hot gases from the burner travel through tubes…

-

The Ultimate Guide to Gas Fired Steam Boilers: Efficiency, Types & Selection

The Ultimate Guide to Gas Fired Steam Boilers: Efficiency, Types & Selection In the world of industrial and commercial heating, few systems are as critical and widely used as the gas fired steam boiler. These powerful workhorses are the backbone of countless operations, from manufacturing plants to hospitals. This guide will demystify gas steam boilers, helping you understand their efficiency, the different types available, and key factors for selection. Understanding Gas Fired Steam Boiler Efficiency Efficiency is paramount when operating a steam system. Modern condensing boilers achieve remarkable thermal efficiency, often exceeding 90%, by capturing latent heat from exhaust gases. Key metrics include Combustion Efficiency, Thermal Efficiency, and Annual Fuel…

-

The Ultimate Guide to Gas Fired Steam Boilers: Efficiency, Types & Benefits

The Ultimate Guide to Gas Fired Steam Boilers: Efficiency, Types & Benefits In the world of industrial and commercial heating, the gas fired steam boiler remains a cornerstone technology. Renowned for their reliability and power, these systems are essential for processes ranging from sterilization and humidification to power generation and heating. This guide delves into everything you need to know, from how they work to selecting the right model for maximum efficiency. How Does a Gas Fired Steam Boiler Work? At its core, a gas fired steam boiler converts water into steam using natural gas or propane as fuel. The burner ignites the gas, creating a flame that heats a…

-

The Ultimate Guide to Biomass Steam Boilers: Efficiency, Benefits & Applications

The Ultimate Guide to Biomass Steam Boilers: Efficiency, Benefits & Applications In the quest for sustainable and cost-effective industrial heating, biomass steam boilers have emerged as a powerful solution. This guide delves into everything you need to know about this renewable energy technology. How Does a Biomass Boiler System Work? A biomass steam boiler converts organic materials like wood chips, pellets, or agricultural waste into thermal energy. This heat turns water into steam, which is then distributed for processing, heating, or power generation. Key Components and Combustion Process The core system includes a fuel feed, combustion chamber, heat exchanger, and emissions control. Advanced automated controls ensure optimal combustion efficiency and…

-

Step Grate Boilers: A Complete Guide to Efficient Combustion Technology

Step Grate Boilers: A Complete Guide to Efficient Combustion Technology In the world of industrial and biomass heating, achieving maximum fuel efficiency and clean combustion is paramount. Among the various technologies available, the step grate boiler stands out as a robust and reliable solution. This guide delves into the mechanics, benefits, and applications of this efficient combustion technology. How Step Grate Combustion Works Unlike traditional flat grates, a step grate system features a series of descending steps. Fuel, such as wood chips or agricultural waste, is fed onto the top step. As combustion occurs, the fuel gradually moves down the staircase-like grate by gravity and mechanical action. This controlled, step-by-step…

-

Step Grate Boilers: The Ultimate Guide to Efficient Solid Fuel Combustion

Step Grate Boilers: The Ultimate Guide to Efficient Solid Fuel Combustion In the world of industrial and commercial heating, achieving maximum efficiency from solid fuels like biomass, wood chips, or refuse-derived fuel (RDF) is a constant challenge. Enter the step grate boiler, a robust and intelligent combustion system designed to tackle this very issue. This guide will explore how these boilers work, their key benefits, and why they are a superior choice for sustainable energy generation. How Does a Step Grate System Work? Unlike traditional stationary grates, a step grate boiler features a moving, stair-like grate assembly. Fuel is fed onto the top step. As the grates move slowly, the…

-

The Ultimate Guide to Biomass Boilers: Efficiency, Costs, and Environmental Benefits

The Ultimate Guide to Biomass Boilers: Efficiency, Costs, and Environmental Benefits Are you exploring sustainable and cost-effective ways to heat your home or business? A biomass boiler could be the powerful, eco-friendly solution you need. This comprehensive guide breaks down everything you need to know about biomass heating systems. How Biomass Boilers Work: A Modern Heating Solution Biomass boilers burn organic materials—like wood pellets, chips, or logs—to generate heat for central heating and hot water. This process is carbon-neutral, as the carbon dioxide released during combustion is roughly equal to what the plants absorbed while growing. Types of Biomass Fuel: Pellets, Chips, and Logs The efficiency and cost of your…

-

The Ultimate Guide to Molten Salt Furnaces: Design, Applications, and Efficiency

The Ultimate Guide to Molten Salt Furnaces: Design, Applications, and Efficiency In the world of industrial heating, few technologies offer the unique blend of high-temperature stability, efficient heat transfer, and operational flexibility as the molten salt furnace. This comprehensive guide delves into the core aspects of these remarkable systems, exploring their design principles, diverse applications, and the key factors driving their efficiency. Core Design and Working Principle At its heart, a molten salt furnace is a thermal fluid heater that uses a mixture of inorganic salts as the heat transfer medium. Unlike traditional systems using water or thermal oil, these salts remain liquid at extremely high temperatures, often between 150°C…

-

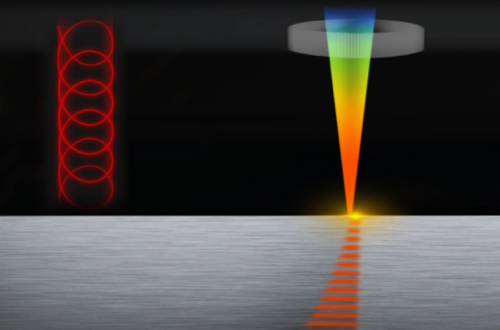

Maximizing Energy Efficiency: A Comprehensive Guide to Waste Heat Boilers

Maximizing Energy Efficiency: A Comprehensive Guide to Waste Heat Boilers In today’s industrial landscape, energy efficiency isn’t just a goal—it’s a necessity for sustainability and cost reduction. One of the most effective technologies for achieving this is the waste heat boiler. This guide will explore how these systems work, their benefits, and how they can transform your operational efficiency. How a Waste Heat Recovery System Works A waste heat boiler captures thermal energy from hot exhaust gases or process streams that would otherwise be released into the atmosphere. This recovered heat is then used to generate steam or hot water, which can be redirected to power other plant processes, generate…