-

AI提示词:从入门到精通,全面掌握智能对话技巧

掌握智能对话技巧:从入门到精通 在人工智能快速发展的今天,智能对话已成为日常生活和工作中不可或缺的一部分。无论是与智能助手交流,还是使用聊天机器人处理业务,掌握高效的对话技巧能显著提升沟通效率。本文将带您从基础概念到高级应用,全面解析智能对话的核心要素。 智能对话的核心原理 智能对话系统基于自然语言处理(NLP)技术,通过分析用户输入生成有意义的回复。理解其工作原理是提升对话技巧的第一步。系统通常包括意图识别、实体提取和上下文管理模块,确保对话流畅自然。 例如,当用户询问“今天天气如何?”时,系统会识别“天气查询”意图,提取“今天”作为时间实体,并调用相关数据返回答案。熟悉这些机制有助于用户更精准地表达需求。 优化提问技巧的方法 清晰的提问能大幅提高智能对话的效果。避免使用模糊或歧义语言,尽量提供具体背景信息。比如, instead of “帮我找餐厅”, try “推荐附近人均200元以内的中式餐厅”。 实践中,可借助ai提示词工具生成结构化问题,这些工具能帮助您设计更有效的对话开场白和后续互动策略。 高级应用与场景实践 在客服、教育、娱乐等领域,智能对话已展现出巨大潜力。企业可通过定制化对话流程处理常见咨询,教育机构能利用互动式对话增强学习体验。关键是结合场景特点设计对话路径。 例如,电商客服机器人可预设商品推荐、退换货政策等对话分支,用户通过简单选择即可快速获取信息。多轮对话设计需注意上下文连贯性,避免用户重复输入。 常见问题解答 如何提高智能对话的准确性? 确保输入信息完整明确,使用标准术语,避免口语化表达。定期更新知识库也能显著提升系统表现。 智能对话适用于哪些行业? 几乎涵盖所有服务型行业,包括医疗预约、金融咨询、旅游规划等,凡需重复性信息交互的场景均可应用。 立即提升您的对话技能 智能对话技术正持续进化,保持学习是关键。通过实践不同场景的对话设计,您将逐渐掌握与AI高效协作的秘诀。 想要获取更多专业提示词和实战案例? 访问我们的资源库,解锁智能对话的无限可能!

-

AI提示词:从入门到精通,掌握智能对话的核心技巧

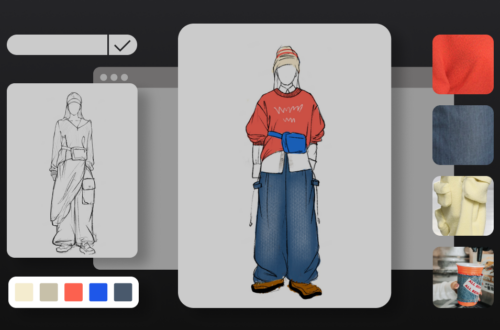

掌握智能对话的核心技巧 随着人工智能技术的飞速发展,AI提示词已成为与智能系统高效交互的关键工具。无论是初学者还是专业人士,掌握提示词的编写技巧都能显著提升对话质量和效率。 提示词结构设计 优质的提示词需要明确目标、设定角色并提供充足背景信息。例如“作为营销专家,请为新能源车撰写三条社交媒体文案,突出环保与科技感”。通过ai提示词结构化设计,可大幅提升AI输出的精准度。 进阶优化策略 尝试以下技巧提升交互效果: 迭代优化:根据初始结果逐步修正指令 示例引导:提供标准样例规范输出格式 场景模拟:构建具体情境增强应答针对性 常见问题解答 Q:如何避免AI生成内容偏离主题? A:通过添加限制条件,如“请用三点说明”“避免使用专业术语”等指令进行约束。 Q:哪些场景最适合使用提示词? A:内容创作、数据分析、编程辅助、语言学习等领域效果显著。 立即提升你的AI交互能力 想要获取更多专业提示词模板?访问我们的资源库获取独家ai提示词工具箱,助你快速成为智能对话专家!

-

提示词工程:打造高效AI交互的秘诀与实战指南

## **提示词工程:打造高效AI交互的秘诀与实战指南** ### **为什么需要掌握提示词工程?** 随着人工智能技术普及,如何与AI高效沟通成为关键。**提示词工程**是通过优化输入指令,精准控制AI输出的核心技术。据统计,合理设计的提示词可将AI响应准确率提升60%以上!掌握这项技能,您将能: – 大幅降低AI生成内容的修改成本 – 快速获得符合场景需求的专业回答 – 挖掘AI工具在营销、编程等领域的深层价值 ### **高效提示词设计四要素** 1. **明确任务目标** 使用「角色扮演+输出格式+示例」结构,例如:“作为资深SEO专家,用表格对比Google与百度的索引规则,参考案例:https://example.com” 2. **控制输出维度** 通过限定长度、排除项、情感倾向等参数精准框定范围,比如:“用200字说明短视频算法逻辑,避免提及抖音具体功能” 3. **动态迭代优化** 采用「诊断-修正」循环:当AI返回结果不理想时,追问“为什么选择这个方案?请从技术层面解释决策依据” 4. **善用链式思维** 复杂任务拆解为多轮对话,例如先要求“生成5个文章选题”,再指令“基于第三个选题写大纲” ### **实战场景应用指南** **▎营销文案优化** – 基础提示:“写一款智能手环的微博文案” – 优化版本:“以科技博主身份创作3条种草文案,突出睡眠监测功能,加入emoji和话题标签,面向25岁职场人群” **▎代码调试辅助** – 基础提示:“为什么这段Python代码报错?” – 优化版本:“分析这段爬虫代码的SSL证书错误,提供具体修改方案和规避策略” ### **常见问题解答** **❓ 提示词越长越好吗?** 不一定。关键在信息密度与逻辑层次,建议先用简练指令测试,逐步增加约束条件。 **❓ 如何评估提示词效果?** 建立可量化的评估标准:内容相关度(0-10分)、格式规范度、信息完整度三个维度打分。 **❓ 哪些工具能提升效率?** 推荐使用专业的提示词工程平台,内置行业模板和实时优化建议。 ### **立即开启高效AI协作** 现在就用这些技巧改造您的下一个提示词!欢迎在评论区分享实践案例,获取定制化优化建议。点击关注获取《提示词设计黄金模板库》!

-

提示词工程:掌握关键词优化的核心策略与实战技巧

掌握关键词优化的核心策略与实战技巧 在当今数字营销时代,关键词优化已成为内容创作不可或缺的一环。通过精准的提示词工程,您不仅能提升内容在Google搜索结果中的排名,还能吸引更多目标受众。本文将带您深入探索关键词优化的核心策略与实战技巧,助您在竞争激烈的搜索引擎世界中脱颖而出。 关键词研究的科学方法 成功的关键词优化始于深入的研究。首先,使用工具如Google Keyword Planner或SEMrush识别高流量关键词和长尾关键词。长尾关键词虽然搜索量较低,但转化率更高,因为它们更具体地匹配用户意图。例如,如果您是营销机构,与其瞄准“数字营销”,不如选择“中小企业数字营销策略”这类更具针对性的词汇。 接下来,分析搜索潜力词汇,关注季节性趋势和用户行为变化。通过提示词工程,您可以将这些关键词自然融入内容中,避免堆砌。记住,Google的算法越来越智能,优先考虑用户体验,因此关键词的使用应流畅且相关。 内容布局与结构优化 一个优化的内容布局能显著提升SEO效果。从标题开始,使用H1标签包含主关键词,如“掌握关键词优化的核心策略”。在正文中,合理使用H2和H3标题,例如用H2突出次级关键词“长尾关键词策略”,并用H3引入LSI词如“语义搜索优化”。 每个段落应聚焦一个主题,并引导读者进入下一部分。例如,在介绍功能后,添加一个过渡句:“了解了基础策略后,让我们看看如何通过实战技巧应用它们。”这不仅能保持内容连贯,还能降低跳出率,提升页面停留时间——这是Google排名的重要因素。 常见问题解答 问:如何避免关键词堆砌?答:通过提示词工程,将关键词自然分布在标题、正文和元描述中。确保内容读起来流畅,优先满足用户需求,而不是机械插入词汇。 问:长尾关键词真的有效吗?答:绝对有效!长尾关键词能精准定位小众受众,提高转化率。例如,在提示词工程中,使用具体短语如“B2B内容营销关键词优化”可以吸引高质量流量。 行动号召 (CTA) 现在,您已经掌握了关键词优化的核心策略,是时候付诸实践了!开始使用这些技巧优化您的内容,并持续监控效果。如果您需要更多指导,请访问我们的资源页面,获取个性化建议。记住,持续学习和调整是SEO成功的关键——立即行动,让您的网站在搜索结果中闪耀!

-

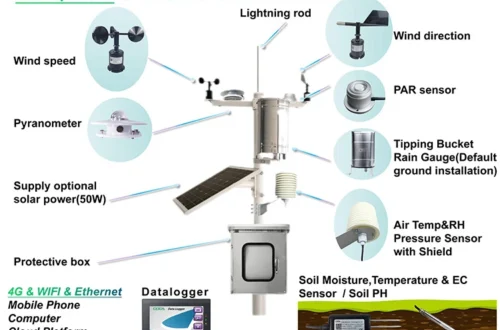

10 Essential Anemometer Uses: From Weather Forecasting to Wind Energy

10 Essential Anemometer Uses: From Weather Forecasting to Wind Energy Anemometers are versatile instruments essential for measuring wind speed and direction. Their anemometer uses span numerous industries, from meteorology to renewable energy. Understanding these applications highlights the tool’s importance in daily operations and large-scale projects. Weather Forecasting and Meteorological Studies Accurate weather prediction relies heavily on anemometers. These devices provide real-time data on wind patterns, helping meteorologists issue timely warnings for storms, hurricanes, and other severe conditions. Wind Energy Production In the renewable energy sector, anemometers are critical for assessing wind farm viability. They measure wind resources to optimize turbine placement and maximize electricity generation efficiently. Aviation and Maritime Safety…

-

What Is an Anemometer Used to Measure? A Complete Guide

# What Is an Anemometer Used to Measure? A Complete Guide An anemometer is a device primarily used to measure wind speed and direction. It plays a crucial role in various industries, from meteorology and aviation to renewable energy and construction. Understanding **what is an anemometer used to measure** can help professionals make informed decisions based on accurate environmental data. what is an anemometer used to measure ## **Detailed Functions of Anemometers** Anemometers are designed to capture and quantify wind characteristics. The most common types include cup, vane, hot-wire, and ultrasonic anemometers. Each type serves specific applications but shares the core function of measuring airflow velocity. ### **Wind Speed Measurement**…

-

What is an Anemometer Used to Measure? A Complete Guide

What is an Anemometer Used to Measure? A Complete Guide An anemometer is a crucial instrument in meteorology and various industries, designed to measure wind speed and direction. Understanding what is an anemometer used to measure can help professionals and enthusiasts make informed decisions based on accurate wind data. Key Functions of An Anemometer Anemometers are primarily used to gauge wind velocity, which is essential for weather forecasting, aviation, and environmental monitoring. They come in different types, including cup, vane, and hot-wire anemometers, each suited for specific applications. Wind Speed Measurement By capturing wind flow, anemometers provide real-time data that aids in predicting weather patterns and ensuring safety in outdoor…

-

The Ultimate Guide to Aluminium Brazing Furnaces: Types, Processes, and Best Practices

The Ultimate Guide to Aluminium Brazing Furnaces: Types, Processes, and Best Practices Aluminium brazing furnaces are essential for creating strong, leak-proof joints in various industries. This guide covers everything you need to know. Types of Aluminium Brazing Furnaces There are several furnace types, including batch and continuous furnaces. Each offers unique benefits for different production needs. Controlled Atmosphere Brazing This process uses a nitrogen-rich environment to prevent oxidation, ensuring high-quality results for aluminium assemblies. Brazing Processes Explained From heating to cooling, each step is crucial. Proper temperature control is key to achieving optimal joint integrity. Flux Application Methods Effective flux usage eliminates oxides and enhances filler metal flow, critical for…

-

The Ultimate Guide to Aluminium Brazing Furnace: Types, Process, and Best Practices

The Ultimate Guide to Aluminium Brazing Furnace: Types, Process, and Best Practices Aluminium brazing is a critical industrial process used to join aluminium components with precision and strength. At the heart of this operation lies the aluminium brazing furnace, a specialized heating system designed to achieve optimal results. This guide explores everything you need to know about these furnaces, from types and processes to industry best practices. Types of Aluminium Brazing Furnaces There are several types of furnaces used for aluminium brazing, each suited to specific applications. Batch furnaces are ideal for small to medium production runs, offering flexibility and ease of operation. Continuous furnaces, on the other hand, are…

-

The Ultimate Guide to Aluminium Brazing Furnaces: Types, Benefits, and Best Practices

Types of Aluminium Brazing Furnaces Aluminium brazing furnaces come in various configurations, each suited to specific industrial needs. Batch furnaces are ideal for smaller production runs, while continuous furnaces excel in high-volume operations. Both types ensure precise temperature control and uniform heating, critical for achieving strong, leak-proof joints in aluminium assemblies. Benefits of Modern Brazing Systems Using an advanced aluminium brazing furnace enhances productivity and joint quality. Key advantages include energy efficiency, reduced oxidation through controlled atmospheres, and compatibility with complex part geometries. These systems also lower operational costs by minimizing material waste and rework. Best Practices for Optimal Results To maximize performance, maintain consistent furnace temperatures and use high-quality…