Top 10 Benefits of Using a Paper Roll Cutting Machine

Top 10 Benefits of Using a Paper Roll Cutting Machine

In today’s fast-paced industrial and commercial environments, efficiency and precision are paramount. A paper roll cutting machine offers a versatile solution for businesses handling paper, film, or fabric rolls. This equipment ensures accurate cuts, reduces waste, and enhances productivity across various applications.

Enhanced Precision and Accuracy

Modern paper roll cutting machines deliver exceptional cutting precision, minimizing material waste and ensuring consistent product quality. This accuracy is crucial for industries like packaging, printing, and textiles, where even minor deviations can lead to significant losses.

Increased Productivity and Efficiency

Automating the cutting process allows businesses to handle large volumes quickly. Operators can set desired dimensions, and the machine executes cuts seamlessly, reducing manual labor and speeding up production cycles.

Cost Savings and Waste Reduction

By optimizing material usage, these machines significantly lower operational costs. Precise cuts mean less scrap, translating into direct savings on raw materials and disposal expenses.

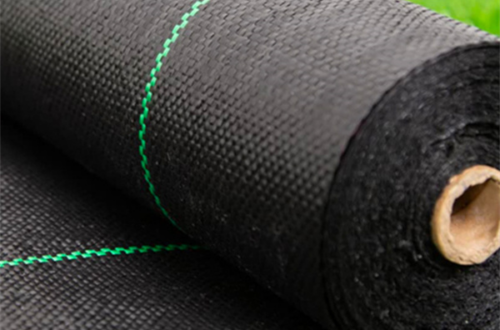

Versatility Across Materials

Beyond paper, these cutters efficiently process non-woven fabrics, plastic films, and other roll materials. This adaptability makes them invaluable for diverse sectors, from manufacturing to retail.

Improved Workplace Safety

Automated cutting reduces the risk of injuries associated with manual handling of blades or heavy rolls. Safety features like emergency stops and protective guards ensure a secure working environment.

User-Friendly Operation

Intuitive controls and programmable settings make paper roll cutting machines accessible even for non-technical staff. Quick setup and minimal training requirements further enhance their appeal.

Customization and Flexibility

Whether you need standard or custom-sized cuts, these machines offer adjustable parameters to meet specific requirements. This flexibility supports bespoke production runs without compromising speed.

Durability and Low Maintenance

Built with robust components, high-quality cutters require minimal upkeep. Regular maintenance is straightforward, ensuring long-term reliability and reduced downtime.

Eco-Friendly Benefits

Reducing material waste contributes to sustainability goals. Efficient cutting means fewer resources consumed and less landfill waste, aligning with green business practices.

Scalability for Business Growth

As your business expands, a paper roll cutting machine can scale with your needs. Upgradeable features and high-capacity models support increasing production demands effortlessly.

Frequently Asked Questions

What materials can a paper roll cutting machine handle?

These machines are designed for paper, cardboard, non-woven fabrics, plastic films, and more. Always check the manufacturer’s specifications for compatibility.

How do I maintain my cutting machine?

Regular cleaning, blade inspections, and software updates (if applicable) are essential. Follow the user manual for specific maintenance schedules.

Can I integrate the cutter into an existing production line?

Yes, many models offer integration options. Consult with your supplier to ensure compatibility with your current setup.

Upgrade Your Operations Today

Investing in a reliable paper roll cutting machine streamlines your workflow, cuts costs, and boosts output. <a