Non-Autoclave Lamination Machine for Composite Manufacturing

# Non-Autoclave Lamination Machine for Composite Manufacturing

## Introduction to Non-Autoclave Lamination Technology

Composite materials have revolutionized modern manufacturing across industries from aerospace to automotive. Traditionally, autoclaves have been the go-to solution for curing composite laminates, but non-autoclave lamination machines are emerging as a game-changing alternative. These innovative systems offer significant advantages in terms of cost, scalability, and operational flexibility.

## How Non-Autoclave Lamination Machines Work

Non-autoclave lamination machines utilize advanced pressure and temperature control systems to achieve high-quality composite curing without the need for expensive autoclave equipment. The process typically involves:

– Layup of composite materials

– Application of controlled vacuum pressure

– Precise temperature regulation

– Controlled cooling cycles

This technology enables manufacturers to produce composite parts with comparable quality to autoclave-cured components while reducing capital investment and operating costs.

## Key Advantages Over Traditional Autoclave Systems

Non-autoclave lamination machines offer several compelling benefits:

### Cost Efficiency

Eliminating the need for large autoclave chambers significantly reduces equipment costs and energy consumption. The smaller footprint also translates to lower facility requirements.

### Scalability

These systems can be more easily scaled to accommodate different production volumes, making them ideal for both prototyping and mass production scenarios.

### Process Flexibility

Manufacturers gain greater control over the curing process parameters, allowing for optimization of cycle times and material properties.

### Reduced Maintenance

Without the high-pressure vessels of autoclaves, non-autoclave systems typically require less maintenance and have longer service lives.

## Applications in Modern Manufacturing

Keyword: non autoclave lamination machine

Non-autoclave lamination technology is finding applications across multiple industries:

– Aerospace components

– Automotive body panels

– Wind turbine blades

– Marine structures

– Sports equipment

The ability to produce high-strength, lightweight composites without autoclaves is particularly valuable for manufacturers looking to expand their composite capabilities without massive capital investments.

## Future Developments in Non-Autoclave Technology

As composite materials continue to evolve, non-autoclave lamination machines are expected to incorporate:

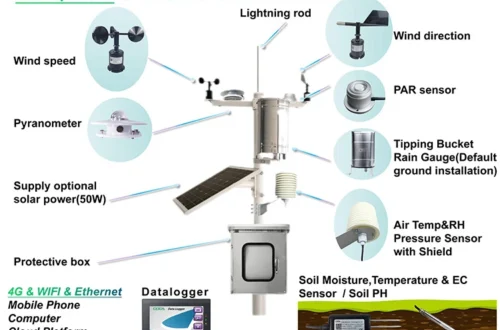

– Advanced sensor networks for real-time process monitoring

– AI-driven process optimization

– Integration with Industry 4.0 manufacturing systems

– Improved energy efficiency

These advancements will further enhance the competitiveness of non-autoclave solutions in the composite manufacturing landscape.

## Conclusion

The non-autoclave lamination machine represents a significant step forward in composite manufacturing technology. By offering high-quality results with lower costs and greater flexibility, these systems are poised to become the standard for many composite production applications. As the technology continues to mature, we can expect even broader adoption across industries seeking the benefits of advanced composite materials without the limitations of traditional autoclave systems.